Catalog

We embrace innovation and creative thinking to pioneer new products.

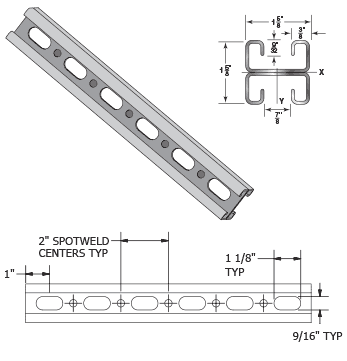

H-164-OSA strut channels are manufactured by a series of forming dies, or rolls, which progressively cold work the strip steel into the desired channel configuration. This method produces a cross-section of uniform dimensions within a tolerance of ±0.015" on outside dimensions.

H-Strut channels are produced from prime structural metals covered by the following specifications.

(See the technical section for additional information.)

Other materials and specifications are available upon request.

H-Strut is available in powder-coated and zinc trivalent finishes. Other finishes are available upon request.

| Span or Unbraced Height (In) | Static Beam Load (X-X Axis) | Max. Allowable Load at Slot Face (lbs) | Column Loading Data | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max Allowable Uniform Load (lbs) | Deflection at Uniform Load (In) | Uniform Load at Deflection | Max. Column Load Applied at C.G. | ||||||||

| Span/180 Deflection (lbs) | Span/240 Deflection (lbs) | Span/360 Deflection (lbs) | Weight of Channel (lbs) | k=0.65 (lbs) | k=0.80 (lbs) | k=1.0 (lbs) | k=1.2 (lbs) | ||||

| 24 | 450 | 0.11 | 450 | 410 | 280 | 2.1 | 1,830 | 5,520 | 5,110 | 4,590 | 4,120 |

| 36 | 300 | 0.24 | 250 | 180 | 120 | 3.1 | 1,690 | 4,650 | 4,120 | 3,530 | 3,050 |

| 48 | 220 | 0.42 | 140 | 100 | 70 | 4.1 | 1,530 | 3,910 | 3,360 | 2,770 | 2,270 |

| 60 | 180 | 0.67 | 90 | 70 | 40 | 5.2 | 1,410 | 3,320 | 2,770 | ** | ** |

| 72 | 150 | 0.96 | 60 | 50 | 30 | 6.2 | 1,260 | 2,830 | 2,270 | ** | ** |

| 84 | 120 | 1.22 | 50 | 30 | 20 | 7.2 | ** | 2,410 | ** | ** | ** |

| 96 | 110 | 1.67 | 30 | 30 | 20 | 8.2 | ** | ** | ** | ** | ** |

| 108 | 100 | 2.16 | 30 | 20 | 10 | 9.3 | ** | ** | ** | ** | ** |

| 120 | 90 | 2.67 | 20 | 20 | NR | 10.3 | ** | ** | ** | ** | ** |

| 144 | 70 | 3.59 | 20 | NR | NR | 12.4 | ** | ** | ** | ** | ** |

| 168 | 60 | 4.88 | NR | NR | NR | 14.4 | ** | ** | ** | ** | ** |

| 192 | 50 | 6.08 | NR | NR | NR | 16.5 | ** | ** | ** | ** | ** |

| 216 | 50 | 8.65 | NR | NR | NR | 18.5 | ** | ** | ** | ** | ** |

| 240 | 40 | 9.49 | NR | NR | NR | 20.6 | ** | ** | ** | ** | ** |

# Bearing Load may limit load | NR = Not Recommended | * Load limited by spot weld shear | ** Not recommended - KL/r exceeds 200