Catalog

We embrace innovation and creative thinking to pioneer new products.

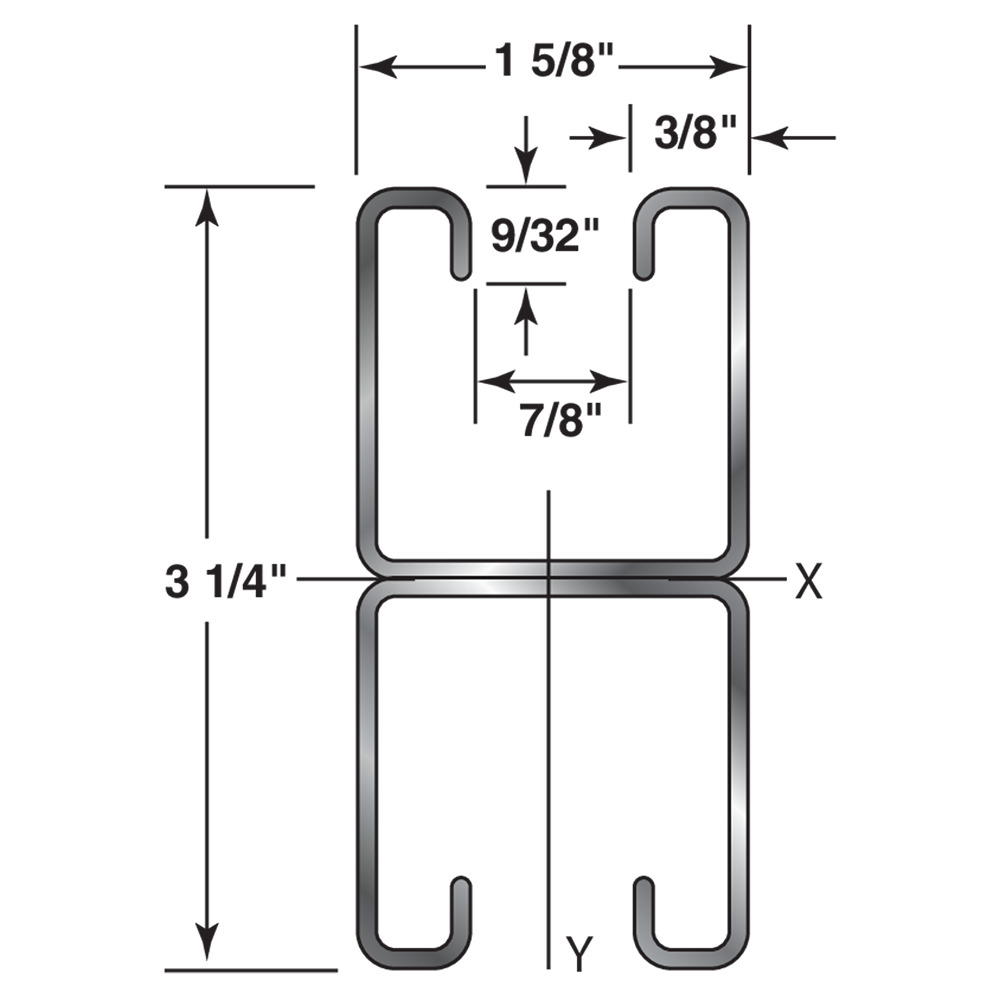

H-134-A strut channels are manufactured by a series of forming dies, or rolls, which progressively cold work the strip steel into the desired channel configuration. This method produces a cross-section of uniform dimensions within a tolerance of ±0.015" on outside dimensions.

H-STRUT® channels are manufactured from high quality, domestically sourced structural steel and roll formed into shape. These products comply with MFMA-4 standards, and beam and column load tables are calculated in accordance with the ANSI North American Specification for the Design of Cold-Formed Steel Structural Members, 2016 Edition.

Channel combinations of two or more elements are spot welded together to form various multiple combinations. The spot welds are placed two inches on center throughout the length of the multiple channel sections.

H-Strut channels are produced in standard 10' and 20' lengths with a tolerance of ±¹⁄₈". Other lengths are available upon request.

H-Strut channels are produced from prime structural metals covered by the following specifications. (See the technical section for additional information.)

H-Strut is available in powder-coated and zinc trivalent finishes. Other finishes are available upon request.

| Span or Unbraced Height(in) | Static Beam Load (X-X Axis) | Max. Allowable Load at Slot Face(lbs) | Max. Column Load Applied at C.G. | Unbraced Length Factor | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max Allowable Uniform Load(lbs) | Deflection at Uniform Load(in) | Uniform Load at Deflection | Column Loading Data | |||||||||

| Span/180 Deflection(lbs) | Span/240 Deflection(lbs) | Span/360 Deflection(lbs) | Weight of Channel(lbs) | k=.65 (lbs) | k=.80 (lbs) | k=1.0 (lbs) | k=1.2 (lbs) | |||||

| 24 | 2,160 * | 0.02 | 2,160 * | 2,160 * | 2,160 * | 5.8 | 4,930 | 17,950 | 17,430 | 16,660 | 15,850 | 1.00 |

| 36 | 2,160 * | 0.06 | 2,160 * | 2,160 * | 2,160 * | 8.7 | 4,790 | 16,760 | 15,850 | 14,630 | 13,480 | 1.00 |

| 48 | 1,860 | 0.13 | 1,860 | 1,860 | 1,860 | 11.6 | 4,600 | 15,440 | 14,230 | 12,790 | 11,580 | 0.99 |

| 60 | 1,480 | 0.19 | 1,480 | 1,480 | 1,250 | 14.5 | 4,240 | 14,140 | 12,790 | 11,320 | 9,350 | 0.93 |

| 72 | 1,240 | 0.28 | 1,240 | 1,240 | 870 | 17.4 | 3,970 | 12,950 | 11,580 | 9,350 | 6,820 | 0.88 |

| 84 | 1,060 | 0.38 | 1,060 | 950 | 640 | 20.3 | 3,630 | 11,930 | 10,250 | 7,210 | 5,010 | 0.82 |

| 96 | 930 | 0.50 | 930 | 730 | 490 | 23.2 | 3,230 | 11,070 | 8,470 | 5,520 | 3,830 | 0.76 |

| 108 | 820 | 0.63 | 770 | 580 | 390 | 26.1 | 2,830 | 9,690 | 6,820 | 4,360 | 3,030 | 0.71 |

| 120 | 740 | 0.78 | 620 | 470 | 310 | 29.0 | 2,460 | 8,260 | 5,520 | 3,530 | ** | 0.65 |

| 144 | 620 | 1.13 | 430 | 320 | 220 | 34.8 | 1,880 | 5,810 | 3,830 | ** | ** | 0.54 |

| 168 | 530 | 1.53 | 320 | 240 | 160 | 40.6 | ** | 4,270 | ** | ** | ** | 0.45 |

| 192 | 460 | 1.98 | 240 | 180 | 120 | 46.4 | ** | 3,270 | ** | ** | ** | 0.39 |

| 216 | 410 | 2.51 | 190 | 140 | 100 | 52.2 | ** | ** | ** | ** | ** | 0.34 |

| 240 | 370 | 3.11 | 160 | 120 | 80 | 58.0 | ** | ** | ** | ** | ** | 0.30 |